This is how a QR code warehouse & inventory management system can help you reduce warehouse picking errors and ensure you’re not losing stock and inventory.

If warehouse picking errors are causing nightmares in the warehouse, a QR code warehouse management & inventory management system (that you build yourself with low-code/no-code) is here to save the day and help you reduce warehouse picking errors.

I’ve worked in warehouses for years. I know what can go wrong.

Warehouse mispicks are a common problem in any industry. Whether it’s retail, B2B or DTC – stuff goes wrong. If you have a warehouse, chances are you’ve sent out the wrong products, struggled to find items or even had customers keep an item 10x more expensive than the product they ordered.

It happens and it’s bad news for business. It’s often no one’s fault.

As you’ll know, warehouse mispicks can lead to delays in shipping, customer dissatisfaction, and increased costs from wasted man-hours and lost inventory. These errors that occur when the wrong item is picked from the warehouse and sent to the customer, resulting in the customer receiving the incorrect product may happen infrequently, but they add up over time.

The costs stack up!

Fortunately, there are ways to reduce the risk of mispicks and improve the overall efficiency of your warehouse operations. In fact, Warehousing is one of the sectors seeing benefits from mobile business apps! So your competitors are jumping on it.

Best of all, you can build it yourself for as little as £/$18* a month… making low-code/no-code totally cheaper than traditional app development!

First of all…Let’s discuss warehouse mispicks

A mispick is an error that occurs when a warehouse worker incorrectly selects and gathers/picks the products listed on a picking document or as directed by warehouse management software. This can lead to delays, increased errors, lost or damaged goods, safety risks in the warehouse, and decreased efficiency and morale among workers.

It causes a lot of headaches. In fact, they cause 5 MAJOR headaches which will likely resonate with you…

This is all from personal experience too, as I have worked in warehouses for many years!

5 key problems warehouse mispicks cause

1- Loss of revenue:

Mispicks can result in lost or damaged goods, which can lead to financial losses for the warehouse and the company. Lost stock, wasted man hours, wear and tear to forklifts unnecessarily.

Reclaiming lost stock is exactly what European Camping Group and Art Systems solved when using a barcode and warehouse inventory scanner built with the forms2 platform.

In fact, the European Camping Group managed to identify that they were losing over $90,000 due to lost stock per year once they started using their warehouse management system!

“We found we were missing about £90,000 worth of linen that just evaporated. Without that evidence of using a warehouse management system, we couldn’t do anything until now.

– James Laverty Deputy Director of Product Delivery at European Camping Group

We can pick up on these issues sooner rather than waiting until the end of the year.”

Read the forms2 case study and testimonial here.

In addition, Steve Hawker at Art Systems managed to free up 114 days a year and rescue upwards of £40,000+ in wasted revenue with forms2 using a barcode scanning app he built using the forms2 platform to streamline warehouse operations and eradicate mispicks.

“Until we built an app with forms2, the warehouse was picking the wrong machine. It looked like it was a very similar product, but there might be a £2,000 – £3,000 difference in the cost and the team were shipping out the wrong item.”

– Steve Hawker at Art Systems

Read the forms2 case study and testimonial here.

2 – Reduced efficiency:

Mispicks can lead to delays in order fulfilment and result in reduced efficiency in the warehouse. This can lead to increased labour costs and some angry customers! Customers getting the wrong products coupled with having to return them isn’t going to result in a good review on Google or Trustpilot!

3- Safety risks:

Mispicks in warehouses or any situation where workers are collecting items can also lead to safety risks for workers, as they may need to handle items that are heavier or more awkward than what they were expecting. For example, if you get the wrong item, you could send hazardous chemicals or materials to unsuspecting customers!

4 – Increased errors:

Errors compound. Those errors lead to lost time. Those errors cause customer dissatisfaction.

Mispicks almost always lead to increased errors in the warehouse, as workers may need to correct their mistakes and re-pick the correct items which can lead to further delays and the team slowing down. It can also lead to products being placed back in the incorrect location to “save time”, causing a never-ending loop of delay as the item you need is not in the right location. this is why you need barcode scanning for warehouses!

5 – Decreased morale:

It’s hard enough working in a warehouse (I know, as I have first-hand experience as I’ve worked in them for years) as such mispicks can be frustrating for warehouse workers, which can lead to decreased morale and reduced productivity as you’re constantly chasing your tail. It’s a tough job!

Workers may become demotivated if they feel like they cannot do their job to the best of their ability – if items are in the wrong location and are being sent out only to be returned, they may have to defend themselves if an angry customer rings up or a less understanding boss questions their abilities. Good warehouse inventory management actually improves morale at work!

6 Ways To Reduce Warehouse Picking Errors

Fortunately, there are several ways you can improve accuracy within your warehouse that will actually make a difference and reduce warehouse picking errors!

1- Use barcode and QR scanning technology:

By using barcode and QR scanning technology for inventory management you can help warehouse workers quickly and accurately scan and verify the products they are picking, reducing the chances of mispicks. In addition, by using barcode scanners or QR code generators, warehouses can accurately track and locate products, reducing the chances of mispicks due to incorrect product placement. By building on our no-code platform, you can reduce warehouse picking errors VERY quickly.

2 – Implement accurate and up-to-date inventory management:

A benefit of QR warehouse management systems is that they can ensure that the warehouse inventory is accurately reflected in the system thanks to the connection with your existing tech stack. Whether you want to connect to SQL Server, SharePoint, Netsuite, BigQuery, Azure, AWS, MySQL, or Salesforce, you can! This can help reduce the chances of mispicks due to incorrect or outdated information.

3 – Take the time to train your workers on the process:

Simply providing proper training and education to warehouse workers on accurately picking and handling products can help reduce the chances of mispicks. Take the time to educate them on things that may happen – 8’s may look like 3’s barcodes can rub off, boxes can look similar, and safety labels must be read etc. Or go one further and allow them to use a QR code system for your inventory management that takes all the hard work out of the job (aside from the lifting that is!)

4 – Implement quality control measures:

Setting up quality control checks at various stages of the picking process can help catch and correct mispicks before they are shipped to customers. Fortunately – automation protocols within a low-code/no-code QR warehouse system app can handle this for you!

5 – Use visualisation aids:

Using visual aids such as labels, signs, and colour coding can help warehouse workers quickly and accurately locate and identify products, reducing the chances of mispicks. Again, a low-code/no-code warehouse management app can help you identify products correctly, even if a label becomes damaged.

6 – Use a real-time tracking system:

Using a real-time tracking system can help warehouse managers and workers monitor the picking process in real time, allowing them to identify and correct mispicks at the exact moment they happen – potentially sending out that annoying BUZZ sound to tell them “nope – wrong item!.” Fortunately, QR codes that you use in the forms platform can generate these real-time tracking features following the product at each stage!

Again, automation in warehousing is key here.

Fortunately, there’s a way you can achieve optimal warehouse performance. It’s with QR code management and low/no-code solutions for your inventory.

What is QR code warehouse management?

QR code warehouse management is a system that uses QR (Quick Response) codes to track and manage inventory in a warehouse and throughout the order and delivery process.

QR codes are small, square-shaped barcodes that can be scanned using a smartphone or a specialised barcode scanner. In a warehouse setting, QR codes can be placed on products, shelves, or storage bins to accurately track the location and movement of your inventory – large or small.

By scanning QR codes in an inventory barcode scanner app, warehouse workers can quickly and accurately access information about the products they are handling, such as product details, expiration dates, and storage requirements.

This can drastically reduce warehouse picking errors 10x and improve efficiency in the warehouse 10 times over. Additionally, warehouse managers can use QR code warehouse management to track inventory levels, identify bottlenecks in the supply chain, and optimise warehouse layouts when connecting to their existing tech stack and analytics software.

It’s a complete 360 overview of your inventory, order and delivery process.

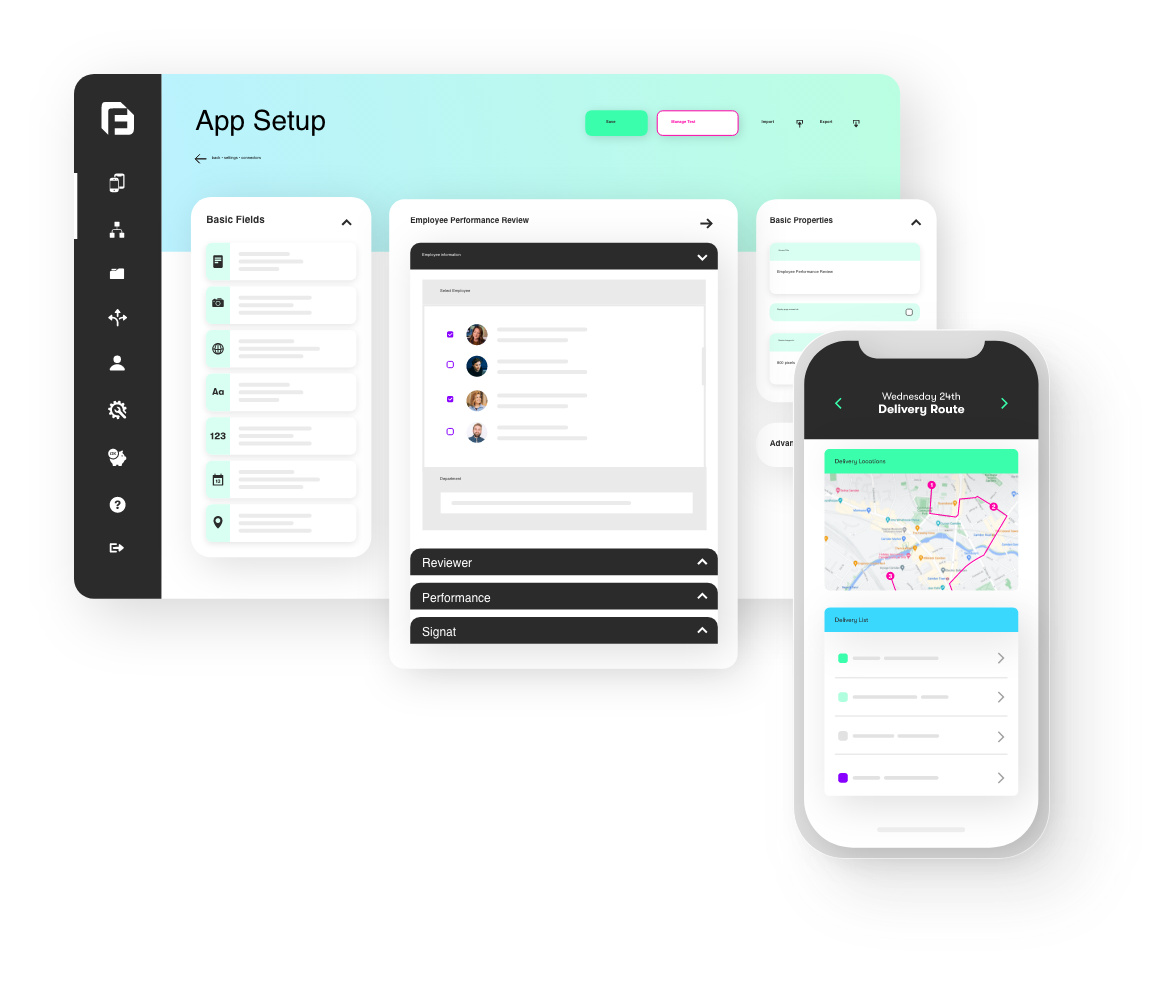

Best of all, you can build this QR inventory barcode scanner app yourself on the forms2 platform in hours or weeks. Not years.

What can QR code warehouse management do for me?

Well, if you build a no-code warehouse scanning app that uses QR codes with multiple levels of detail and required fields or even automated skip logic, it can improve the order, pick, and dispatch process in several ways by automating all the processes that usually would suffer from human error.

A warehouse management app with barcode scanning or QR code scanning that you built with forms2, can be used by warehouse workers to quickly and easily scan the QR code on a product’s packaging, which can then provide detailed information about the product, including its name, quantity, location, and status. You have ALL the info you need in the palm of your hand!

Let’s look at 2 scenarios…and see if this sounds familiar. A warehouse without automation, and the other with automation.

If you’re a warehouse manager, then you’ll know the process of order, warehouse pick, and dispatch involves several steps, as follows: Full disclosure – scenario #1 was what I had to put up with for years!

| Scenario #1 – WITHOUT AUTOMATION | Scenario #2 – WITH AUTOMATION |

| The order processed on a using piece of paper in your warehouse | A Warehouse Using A QR Code Management System / Warehouse Barcode Scanner App |

| A customer places an order for a product through a website, app, or another online platform. | A customer places an order for a product through a website, app, or another online platform. |

| The order is received by your warehouse, where it’s (hopefully) automatically entered into the system and assigned a unique order number. | The order is received by your warehouse, where it’s automatically entered into the system and assigned a unique order number. |

| A warehouse worker logs onto the system and checks the orders that need to be picked. | A warehouse worker is alerted on their smartphone or tablet via push notifications that 5 new orders need to be picked. |

| They then print a piece of paper with all of the orders they can manage in one trip. | They are shown the exact locations of these products. They will be in the correct place because QR codes are assigned to locations as well as products. |

| The warehouse worker picks the product from its location, visually checking the order number which has hopefully been placed in the correct location. Then they bring it to a designated packing area. | The worker uses a phone or tablet with the low-code/no-code warehouse barcode scanner /QR code scanner on their device to confirm they have the correct product. They could also scan a QR code from the racking or isle description, to confirm/check they are in the right location |

| The product is carefully packed and a label is then generated manually with the customer’s shipping information. | The warehouse worker picks the CORRECT product from its location in the warehouse and brings it to a designated packing area. |

| The packed product is then sent to the shipping department, where it’s loaded onto a truck and sent to the customer. | The product is carefully packed and labelled with the customer’s shipping information which has been AUTOMATICALLY printed on confirmation of the correct product. The printing label will not be printed on incorrect products. |

| The customer receives the product and the order is then marked as complete by the courier agency which (is hopefully) connected to your warehouse system. | As the QR code has been scanned, the ‘in stock’ quantity in the company’s ERP system can automatically be deprecated, giving up to the minute accurate stock levels. |

| The packed product is then sent to the shipping department which also confirms via the warehouse barcode scanning app and inventory management that they have received it. | |

| It’s loaded onto a truck and sent to the customer. | |

| The customer receives the product and the order is marked as complete in the warehouse management system. | |

| The problem with this process: | The benefit of this process: |

| Unfortunately, 5 out of 10 products that your warehouse operative picked were in the incorrect location. 4 of which needed a forklift. | For each of the 11 points above, as the order progresses, the company’s ERP systems can be updated with the current status, and this can be presented to the customer using your existing eCommerce solution. |

| 3 out of 10 products were incorrect and the warehouse operative simply mistook an “8” for a “3” on the barcode. | Throughout this process, the QR code warehouse management system is used to identify the correct product. It’s then tracked throughout the whole process which then ensures that it’s properly fulfilled and dispatched to the customer. |

| 3 products were delivered incorrectly to your customers and had to be sent back. This costs you money in terms of man hours, courier collection and results in a 1-star review on Trustpilot. | The customer is happy. They leave a 5-star review and are happy to be returning customers. |

| You have wasted money. Wasted your staff’s time and your customers aren’t happy. | With one scan of a QR code, you have ensured the 100% accuracy and efficiency of the warehouse operation and eradicated errors or mispicks. |

It’s safe to say QR code warehouse management systems help make life easier with automation.

Automation eradicated human error!

What sounds better? Scenario 1 or 2?

9 Benefits of QR code warehouse management that will help you TODAY!

In summary, here are 9 ways a QR code warehouse management system and warehouse scanner app will improve your operations

- It will save you money. Like A LOT! European camping Group saved 90k per year!

- Helps reduce the risk of mispicks by verifying the correct product is being picked

- Improves inventory management by tracking the location and quantity of each product within the warehouse

- Increases efficiency by optimising warehouse layout and reducing time and effort required to locate and pick products

- Improves communication and coordination within the warehouse by allowing for the sharing of information and updates

- Can be quickly and easily tailored to the specific needs of the warehouse and the items being picked using a low-code/no-code platform

- Can be used to track inventory levels, identify bottlenecks in the supply chain, and optimise warehouse layouts

- It WILL improve customer satisfaction, and generate more positive reviews.

- Improved productivity – warehouse operatives know exactly what they need to do.

Can I build my own QR code warehouse management system?

Yes you can. In a matter of days. And our mobile forms and business apps case studies & forms2 testimonials back that up!

You can even build an app to handle ‘goods in’. By generating a QR code and using a mobile printer for the carton label, the QR code, product description etc, can be automatically recorded from the app into the ERP system. You can create a full-service warehouse goods-in/goods-out system!

Building your own QR code warehouse management system app using low-code/no-code technology is a quick and easy way to improve the accuracy and efficiency of your warehouse operations.

Final thoughts on using forms2 for QR code warehouse management systems

In case you haven’t already guessed, using a warehouse scanning app can help to eradicate mispicks, improve inventory management, and increase the overall efficiency of your warehouse operations without damaging your IT budget.

By implementing a warehouse scanning app, you’ll improve the accuracy and efficiency of your warehouse, and provide a better experience for your customers.

Overall, forms2 is the best choice for building your own QR code warehouse management system app, offering a combination of affordability, ease of use, scalability, and a short time to market. With prices starting at just $18-25* per month and the help of our platform specialists, you’ll be unstoppable with automation and mobile forms!

Speak to our platform specialists today about creating your own low-code/no-code barcode scanner app specifically for warehouse use. We’ll get you up and running with QR code warehouse management systems that you can build yourself! Or any other kind of app you want to build with forms2!

14-day trial. No Fee. No obligation. Try today.

This was written by a real human and fact-checked.

Learn how TD Construction Testing saved over £30,000 per year, cut admin time by 80% with digital forms.